Silver Alloys: Designed for Unmatched Performance in Every Project

Silver alloys are a popular choice for many industries, and it’s easy to see why. With their excellent electrical conductivity, strength, and resistance to corrosion, these materials stand out in demanding environments. Here’s why you should consider silver alloys for your next project:

- Top-Notch Conductivity: Silver is the best conductor of electricity, making it essential for electronics, connectors, and circuit boards.

- Precision and Durability: Whether it’s for medical devices, aerospace, or any application requiring fine details, silver alloys provide the durability and reliability you need.

Long-Lasting Performance: Silver alloys resist corrosion naturally, offering longevity even in tough conditions, which makes them perfect for high-performance applications.

We offer a wide range of silver products, tailored to fit the specific needs of your projects. Here’s what we have:

Silver Foils & Strips

- Thickness: 0.1mm to 5mm

- Width: 3mm to 100mm

- Perfect for electronics, precision manufacturing, and even decorative designs. Silver foils are commonly used for connectors, circuit boards, and artistic creations, offering the ideal balance of flexibility and strength.

Silver Rods

- Diameter: 1mm to 4mm

- Length: 350mm to 1000mm

- Whether you’re creating precise components or welding, our silver rods are strong, reliable, and ready for your next project. They’re designed for high-performance tasks in various industries.

Silver Wire

- Gauge: 0.35mm to 5mm

- Available in a range of gauges, our silver wire is perfect for electrical contacts, wiring, and precision soldering. It’s widely used in electronics, automotive parts, and telecommunications.

Where Can You Use Silver Alloys?

Silver alloys are incredibly versatile, which is why they’re found in so many different industries. Here are a few areas where silver alloys truly shine:

- Electronics: Silver’s top-tier conductivity makes it the perfect material for circuit boards, connectors, and wiring in all kinds of electronic devices.

- Jewelry Making: If you’re crafting jewelry, silver alloys offer a combination of beauty and durability. They’re perfect for creating timeless pieces that last.

- Medical Devices: Silver alloys are used in making electrodes, sensors, and other medical components because of their biocompatibility and excellent conductivity.

- Aerospace: Silver alloys are used in critical aerospace components that require both strength and reliability, ensuring high performance even under extreme conditions.

Telecommunications: With silver alloys, you can trust that your telecommunications systems will deliver high-speed, reliable performance.

| SLIVER BLAZING ALLOYS - CADMIUM FREE GARDES | |||||||

| Palis Sliver Grade of Brazing alloy | Nominal Composition % | Melting Range | international Strandards | ||||

| Ag | Cu | Zn | Other | C | DIN:8512 | AWS:A5.8 | |

| Pali Sliver 925 | 92.5 | 7.3 | - | 0.20Li | 760-890 | - | baG19 |

| used in higher brazing temperature, where precipitation hardening heat treatment in brazing are combined | |||||||

| Pali Sliver 85 | 85 | - | - | 15Mn | 960-970 | LAg85 | BAg23 |

| A high temperature free following filler metal. mainly in brazing stainless steel, nickel based cobalt based alloy or high temperature applications. | |||||||

| Pali Sliver 83 | 83 | 15 | 2 | - | 780-830 | LAg83 | - |

| mainly used fo brazing and braze welding of precision sliver equipment orprecision silver linings of chemical equipments | |||||||

| Pali sliver 75 | 75 | 22 | 3 | - | 780-830 | LAg75 | - |

| for Brazing Of object made of sliver alloys which are to enameled afterwards | |||||||

| Pali sliver 72 | 72 | 28 | - | - | 779 | LAg72 | BAg8 |

| for ferrous and nonferrous base alloys especially for thin section of stainless steel | |||||||

| Pali silver 71.5 | 71.5 | 28 | - | 0.5NI | 780-795 | - | - |

| Suitable for both ferrous and non ferrous alloys | |||||||

| Pali silver 70 | 70 | 20 | 10 | - | 690-740 | - | BAg10 |

| Used particularly for joining starling sliver. the color after brazing approximates the color of sterling sliver | |||||||

| Pali silver 67 | 67 | 23 | 10 | - | 700-760 | LAg67 | - |

| Used for brazing of sliver goods made of sliver alloys. | |||||||

| Pali sliver 65 | 65 | 28 | - | 5Mn,2Nl | 750-850 | - | - |

| For brazing cover and similar alloys to copper n vacuum tubes; as jet engine seals | |||||||

| Pali sliver 64 | 64 | 20 | 16 | - | 690-720 | LAg64 | BAg9 |

| used particularly for joining starling sliver. the color after bazing approximates the color of sterling sliver | |||||||

| Pali sliver 63 | 63 | 28.5 | - | 2NI,2Sn | 690-800 | - | BAg21 |

| used particularly for joining starling sliver. the color after bazing approximates the color of sterling sliver | |||||||

| Pali Sliver 61 | 61 | 29 | 10 | - | 690-735 | - | - |

| In particularly suitable for joining electrical components requiring high electrical conductivity and close colour match of sliver also used for brazing sliver goods. | |||||||

| Pali sliver 60 | 60 | 26 | 14 | - | 695-730 | LAg60 | - |

| For Brazing monel, nikel alloys and silver. | |||||||

| Pali silver 60Sn | 60 | 30 | - | 10Sn | 600-720 | - | BAg18 |

| Its tin content, helps promote wetting stainless steel nikel base alloys carbon steel, is specially for vacuum applications and brazing small parts most in protective |

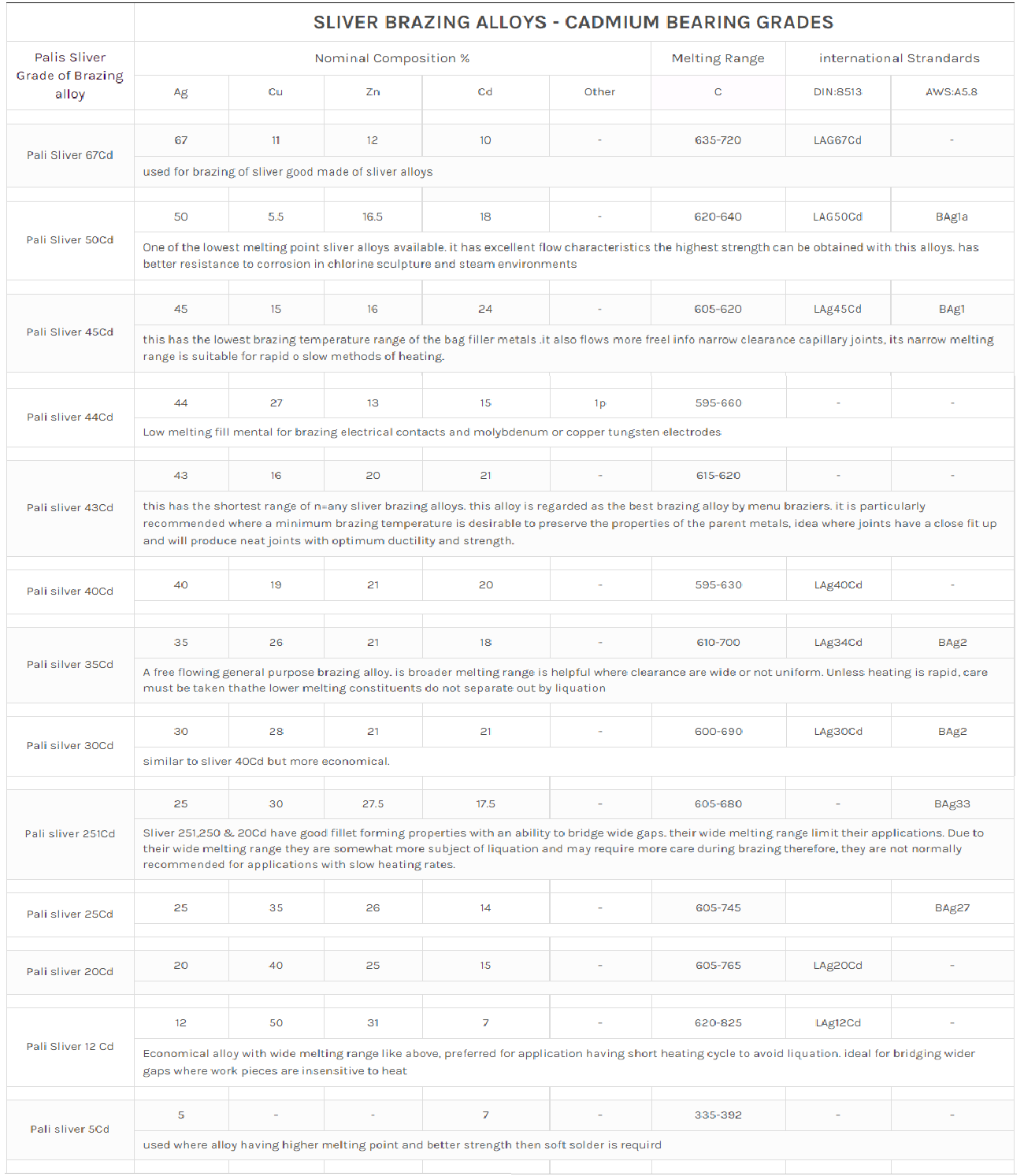

| SLIVER BRAZING ALLOYS - CADMIUM BEARING GRADES | ||||||||

| Palis Sliver Grade of Brazing alloy | Nominal Composition % | Melting Range | international Strandards | |||||

| Ag | Cu | Zn | Cd | Other | C | DIN:8513 | AWS:A5.8 | |

| Pali Sliver 67Cd | 67 | 11 | 12 | 10 | - | 635-720 | LAG67Cd | - |

| used for brazing of sliver good made of sliver alloys | used for brazing of sliver good made of sliver alloys | used for brazing of sliver good made of sliver alloys | used for brazing of sliver good made of sliver alloys | used for brazing of sliver good made of sliver alloys | used for brazing of sliver good made of sliver alloys | used for brazing of sliver good made of sliver alloys | used for brazing of sliver good made of sliver alloys | |

| Pali Sliver 50Cd | 50 | 5.5 | 16.5 | 18 | - | 620-640 | LAG50Cd | BAg1a |

| One of the lowest melting point sliver alloys available. it has excellent flow characteristics the highest strength can be obtained with this alloys. has better resistance to corrosion in chlorine sculpture and steam environments | ||||||||

| Pali Sliver 45Cd | 45 | 15 | 16 | 24 | - | 605-620 | LAg45Cd | BAg1 |

| this has the lowest brazing temperature range of the bag filler metals .it also flows more freel info narrow clearance capillary joints, its narrow melting range is suitable for rapid o slow methods of heating. | this has the lowest brazing temperature range of the bag filler metals .it also flows more freel info narrow clearance capillary joints, its narrow melting range is suitable for rapid o slow methods of heating. | this has the lowest brazing temperature range of the bag filler metals .it also flows more freel info narrow clearance capillary joints, its narrow melting range is suitable for rapid o slow methods of heating. | this has the lowest brazing temperature range of the bag filler metals .it also flows more freel info narrow clearance capillary joints, its narrow melting range is suitable for rapid o slow methods of heating. | this has the lowest brazing temperature range of the bag filler metals .it also flows more freel info narrow clearance capillary joints, its narrow melting range is suitable for rapid o slow methods of heating. | this has the lowest brazing temperature range of the bag filler metals .it also flows more freel info narrow clearance capillary joints, its narrow melting range is suitable for rapid o slow methods of heating. | this has the lowest brazing temperature range of the bag filler metals .it also flows more freel info narrow clearance capillary joints, its narrow melting range is suitable for rapid o slow methods of heating. | this has the lowest brazing temperature range of the bag filler metals .it also flows more freel info narrow clearance capillary joints, its narrow melting range is suitable for rapid o slow methods of heating. | |

| Pali sliver 44Cd | 44 | 27 | 13 | 15 | 1p | 595-660 | - | - |

| Low melting fill mental for brazing electrical contacts and molybdenum or copper tungsten electrodes | Low melting fill mental for brazing electrical contacts and molybdenum or copper tungsten electrodes | Low melting fill mental for brazing electrical contacts and molybdenum or copper tungsten electrodes | Low melting fill mental for brazing electrical contacts and molybdenum or copper tungsten electrodes | Low melting fill mental for brazing electrical contacts and molybdenum or copper tungsten electrodes | Low melting fill mental for brazing electrical contacts and molybdenum or copper tungsten electrodes | Low melting fill mental for brazing electrical contacts and molybdenum or copper tungsten electrodes | Low melting fill mental for brazing electrical contacts and molybdenum or copper tungsten electrodes | |

| Pali sliver 43Cd | 43 | 16 | 20 | 21 | - | 615-620 | - | - |

| this has the shortest range of n=any sliver brazing alloys. this alloy is regarded as the best brazing alloy by menu braziers. it is particularly recommended where a minimum brazing temperature is desirable to preserve the properties of the parent metals, idea where joints have a close fit up and will produce neat joints with optimum ductility and strength. | ||||||||

| Pali silver 40Cd | 40 | 19 | 21 | 20 | - | 595-630 | LAg40Cd | - |

| Pali silver 35Cd | 35 | 26 | 21 | 18 | - | 610-700 | LAg34Cd | BAg2 |

| A free flowing general purpose brazing alloy. is broader melting range is helpful where clearance are wide or not uniform. Unless heating is rapid, care must be taken thathe lower melting constituents do not separate out by liquation | ||||||||

| Pali silver 30Cd | 30 | 28 | 21 | 21 | - | 600-690 | LAg30Cd | BAg2 |

| similar to sliver 40Cd but more economical. | ||||||||

| Pali sliver 251Cd | 25 | 30 | 27.5 | 17.5 | - | 605-680 | - | BAg33 |

| Sliver 251,250 & 20Cd have good fillet forming properties with an ability to bridge wide gaps. their wide melting range limit their applications. Due to their wide melting range they are somewhat more subject of liquation and may require more care during brazing therefore, they are not normally recommended for applications with slow heating rates. | ||||||||

| Pali sliver 25Cd | 25 | 35 | 26 | 14 | - | 605-745 | BAg27 | |

| Pali sliver 20Cd | 20 | 40 | 25 | 15 | - | 605-765 | LAg20Cd | - |

| Pali Sliver 12 Cd | 12 | 50 | 31 | 7 | - | 620-825 | LAg12Cd | - |

| Economical alloy with wide melting range like above, preferred for application having short heating cycle to avoid liquation. ideal for bridging wider gaps where work pieces are insensitive to heat | ||||||||

| Pali sliver 5Cd | 5 | - | - | 7 | - | 335-392 | - | - |

| used where alloy having higher melting point and better strength then soft solder is requird | used where alloy having higher melting point and better strength then soft solder is requird | used where alloy having higher melting point and better strength then soft solder is requird | used where alloy having higher melting point and better strength then soft solder is requird | used where alloy having higher melting point and better strength then soft solder is requird | used where alloy having higher melting point and better strength then soft solder is requird | used where alloy having higher melting point and better strength then soft solder is requird | used where alloy having higher melting point and better strength then soft solder is requird | |

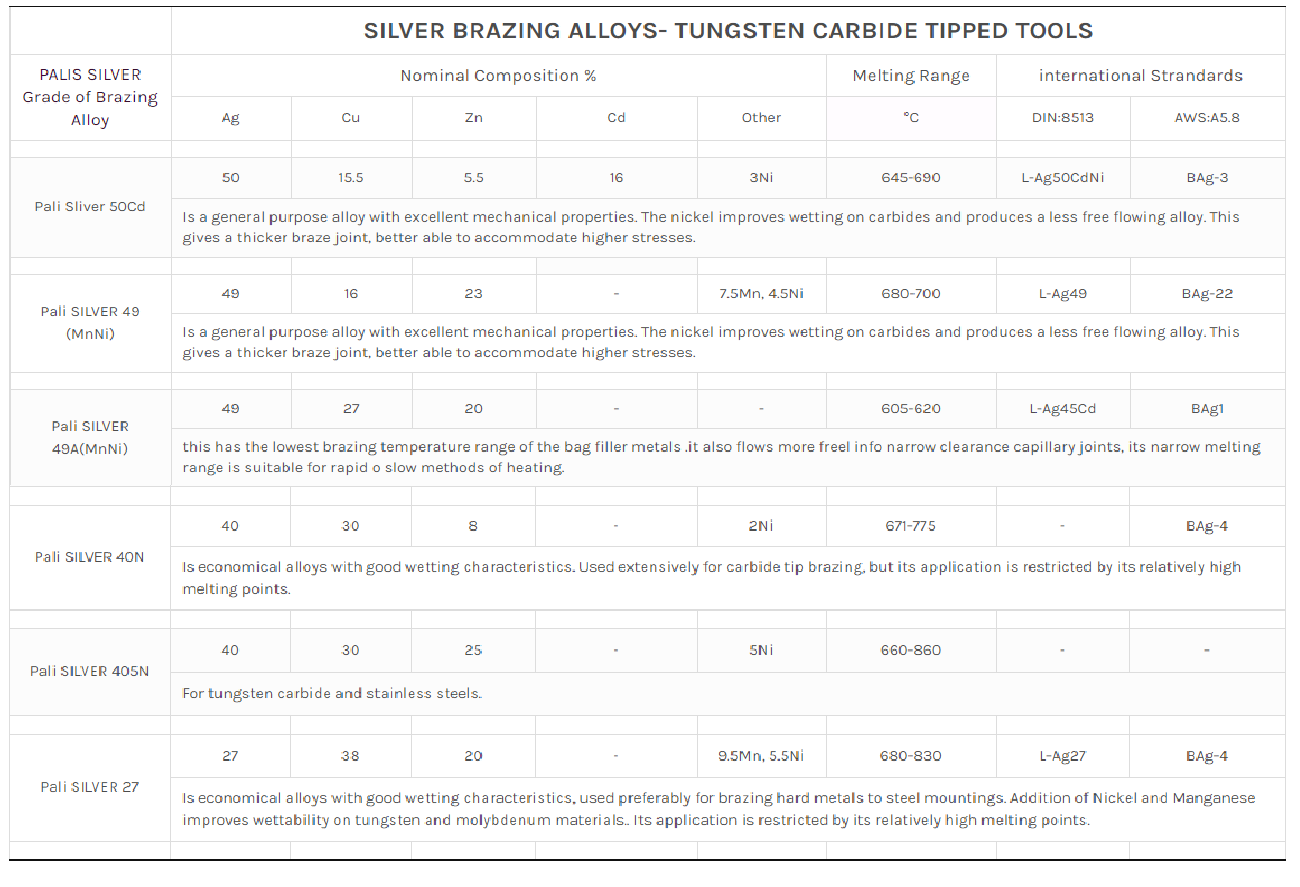

| SILVER BRAZING ALLOYS- TUNGSTEN CARBIDE TIPPED TOOLS | ||||||||

| PALIS SILVER Grade of Brazing Alloy | Nominal Composition % | Melting Range | international Strandards | |||||

| Ag | Cu | Zn | Cd | Other | °C | DIN:8513 | AWS:A5.8 | |

| Pali Sliver 50Cd | 50 | 15.5 | 5.5 | 16 | 3Ni | 645-690 | L-Ag50CdNi | BAg-3 |

| Is a general purpose alloy with excellent mechanical properties. The nickel improves wetting on carbides and produces a less free flowing alloy. This gives a thicker braze joint, better able to accommodate higher stresses. | ||||||||

| Pali SILVER 49 (MnNi) | 49 | 16 | 23 | - | 7.5Mn, 4.5Ni | 680-700 | L-Ag49 | BAg-22 |

| Is a general purpose alloy with excellent mechanical properties. The nickel improves wetting on carbides and produces a less free flowing alloy. This gives a thicker braze joint, better able to accommodate higher stresses. | Is a general purpose alloy with excellent mechanical properties. The nickel improves wetting on carbides and produces a less free flowing alloy. This gives a thicker braze joint, better able to accommodate higher stresses. | Is a general purpose alloy with excellent mechanical properties. The nickel improves wetting on carbides and produces a less free flowing alloy. This gives a thicker braze joint, better able to accommodate higher stresses. | Is a general purpose alloy with excellent mechanical properties. The nickel improves wetting on carbides and produces a less free flowing alloy. This gives a thicker braze joint, better able to accommodate higher stresses. | Is a general purpose alloy with excellent mechanical properties. The nickel improves wetting on carbides and produces a less free flowing alloy. This gives a thicker braze joint, better able to accommodate higher stresses. | Is a general purpose alloy with excellent mechanical properties. The nickel improves wetting on carbides and produces a less free flowing alloy. This gives a thicker braze joint, better able to accommodate higher stresses. | Is a general purpose alloy with excellent mechanical properties. The nickel improves wetting on carbides and produces a less free flowing alloy. This gives a thicker braze joint, better able to accommodate higher stresses. | Is a general purpose alloy with excellent mechanical properties. The nickel improves wetting on carbides and produces a less free flowing alloy. This gives a thicker braze joint, better able to accommodate higher stresses. | |

| Pali SILVER 49A(MnNi) | 49 | 27 | 20 | - | - | 605-620 | L-Ag45Cd | BAg1 |

| Pali SILVER 49A(MnNi) | this has the lowest brazing temperature range of the bag filler metals .it also flows more freel info narrow clearance capillary joints, its narrow melting range is suitable for rapid o slow methods of heating. | |||||||

| Pali SILVER 40N | 40 | 30 | 8 | - | 2Ni | 671-775 | - | BAg-4 |

| Pali SILVER 40N | Is economical alloys with good wetting characteristics. Used extensively for carbide tip brazing, but its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics. Used extensively for carbide tip brazing, but its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics. Used extensively for carbide tip brazing, but its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics. Used extensively for carbide tip brazing, but its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics. Used extensively for carbide tip brazing, but its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics. Used extensively for carbide tip brazing, but its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics. Used extensively for carbide tip brazing, but its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics. Used extensively for carbide tip brazing, but its application is restricted by its relatively high melting points. |

| Pali SILVER 405N | 40 | 30 | 25 | - | 5Ni | 660-860 | - | - |

| Pali SILVER 405N | For tungsten carbide and stainless steels. | For tungsten carbide and stainless steels. | For tungsten carbide and stainless steels. | For tungsten carbide and stainless steels. | For tungsten carbide and stainless steels. | For tungsten carbide and stainless steels. | For tungsten carbide and stainless steels. | For tungsten carbide and stainless steels. |

| Pali SILVER 27 | 27 | 38 | 20 | - | 9.5Mn, 5.5Ni | 680-830 | L-Ag27 | BAg-4 |

| Pali SILVER 27 | Is economical alloys with good wetting characteristics, used preferably for brazing hard metals to steel mountings. Addition of Nickel and Manganese improves wettability on tungsten and molybdenum materials.. Its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics, used preferably for brazing hard metals to steel mountings. Addition of Nickel and Manganese improves wettability on tungsten and molybdenum materials.. Its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics, used preferably for brazing hard metals to steel mountings. Addition of Nickel and Manganese improves wettability on tungsten and molybdenum materials.. Its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics, used preferably for brazing hard metals to steel mountings. Addition of Nickel and Manganese improves wettability on tungsten and molybdenum materials.. Its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics, used preferably for brazing hard metals to steel mountings. Addition of Nickel and Manganese improves wettability on tungsten and molybdenum materials.. Its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics, used preferably for brazing hard metals to steel mountings. Addition of Nickel and Manganese improves wettability on tungsten and molybdenum materials.. Its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics, used preferably for brazing hard metals to steel mountings. Addition of Nickel and Manganese improves wettability on tungsten and molybdenum materials.. Its application is restricted by its relatively high melting points. | Is economical alloys with good wetting characteristics, used preferably for brazing hard metals to steel mountings. Addition of Nickel and Manganese improves wettability on tungsten and molybdenum materials.. Its application is restricted by its relatively high melting points. |

Why Palis Trading?

When you partner with us, you’re getting more than just high-quality silver alloys. You’re getting a team dedicated to helping you succeed. We’re here to make sure you have exactly what you need, when you need it. Here’s what you can expect from Palis Trading:

- Custom Solutions: We understand that every project is unique. If you need specific sizes or forms, we can customize our silver alloys to suit your needs.

- Expert Guidance: Not sure which silver product is right for your project? Our experienced team is always here to help, offering advice and support every step of the way.

- On-Time Delivery: We know how important deadlines are. That’s why we ensure quick and reliable delivery, so you never have to worry about delays.